3d printing technology is pacing up industries across domains. Be it automotive, aerospace, or manufacturing — it is transforming how companies used to build products. Earlier, this technology was only accessible to big companies and manufacturing units.

However, now even small businesses can take advantage of additive manufacturing and grow their business seamlessly. From rapid prototyping to product manufacturing and innovating new concepts, small & medium-sized companies can also experience 3d printing. As this technology requires a smaller workforce, it’s ideal to use it when working with limited resources.

As compared to traditional manufacturing services, 3d printing is fast, innovative and gives an edge to the company to take the lead in its industry. With the growth in on-demand manufacturing services across domains, several professional companies are offering 3d printing service in Perth, Melbourne and other places. Wondering how exactly does the 3d printing works and what are the benefits for small businesses? We have researched everything that you need to know.

How Does 3D Printing Technology Work?

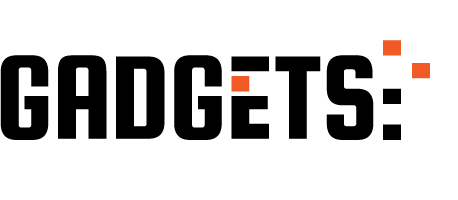

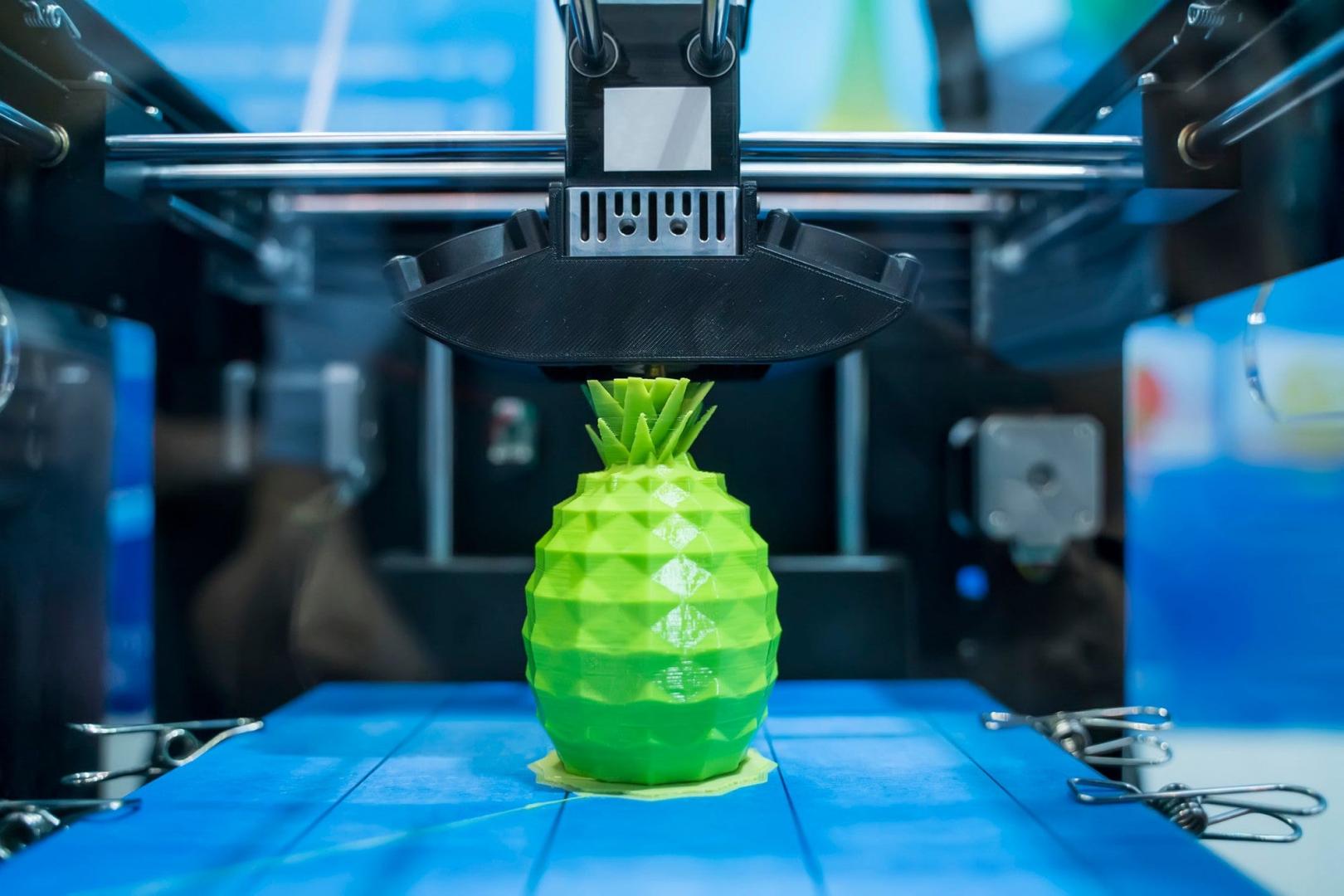

3d printing is an additive process in which the machine creates objects by laying one layer upon another till the entire design is ready. It is similar to a traditional inkjet printer, but 3d printing lets creators print very intricate designs with various materials and surface finishes. This technology uses materials that are either available in bulk spool or are in powdered form. Additive manufacturing offers higher accuracy, faster turnaround time and more flexibility. Below are the main steps of 3d printing.

3D Modelling

The 3d printing process begins with creating a 3d model of the design that the printers will make. Using advanced 3D CAD design software, engineers prepare a 3d model that contains all the intricate details of the final product. With 3d modelling software, engineers can design a complex design in less time with higher accuracy. Once the design is ready with all details intact, it’s prepared to go towards the next phase, slicing.

Slicing

The CAD files are large, and the 3d printer can’t process such large data sets in real-time. To solve this problem, engineers use slicing software to make the CAD model interpretable to the 3d printer as the machines can not directly understand the 3d models.

The slicing software slices down the model into hundreds or even thousands of layers. The slicing software then scans every layer and instructs the printer to move the printing nozzle and recreate the layer. In simple terms, slicing software breaks down the design and tells 3d printers how the printing head should move to create the final object.

3D Printing Process

After the slicing is complete, it’s time for the actual 3d printing, where the machine will start laying down material layers one by one and create the physical object. The working of 3d printers is straightforward and uniform. First, the equipment will print one layer, and once the layer solidifies, the printer ejects the second layer on top of the last layer. This 3d print process continues till the design is complete.

Post-Processing

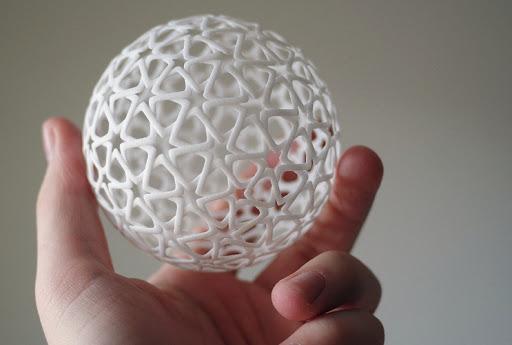

Once the 3d printed object is ready, it goes for post-processing work where engineers give the desired surface finish before delivering it. The best part about this modern 3d printing is that you get many printing options as well as in the surface finishing.

Benefits of 3d Printing Solutions to Small Businesses

Earlier, 3d printing was only an add-on to the mainstream manufacturing process. However, with personalized product requirements, the demand for this technology is growing in small businesses.

Rapid Prototyping

Using a 3d printer, it becomes easier for designers to prepare a proof of concept and start testing the design without any delay. 3d printing technology is widely popular for its rapid prototyping capabilities, and it’s ideal for testing your new geometries and innovations. Additive manufacturing will help you improve the research and development process. It is the best way to design, validate, test and prepare new complex designs in budget with a faster turnaround time.

On-Demand Printing

As compared to the traditional approach, additive manufacturing offers small businesses the power of on-demand printing. Earlier, companies needed to wait for weeks or even months to get the products in their hands. However, by opting for a professional 3d printing service provider, the production cycle is cut to only a couple of days. This flexibility gives a competitive advantage over others, and lets companies deliver more innovative products in a shorter turnaround. The digital manufacturing process helps business owners with optimized operations

Multiple Options

For small companies, it becomes complex to look up to more innovative manufacturing options due to a restricted budget. Earlier, only big companies with a substantial R&D budget could try out multiple options before launching the final product. However, with the availability of 3d printers and printing services, the small business now has access to limitless customization options. Be it material selection or surface finishing — 3d printing opens the opportunity to innovate without burning more budget.

Reduced Production Cost

Several small companies deal with hiked manufacturing costs while using the traditional production methods. 3d printing solves this problem for small businesses as it offers the flexibility to print design depending on the current demand. Be it ten items or hundred items, 3d printing companies can fulfil the order with shorter lead times. Due to this convenience to small businesses, they don’t require to maintain a large inventory that needs substantial capital.

Mass Customization

3d printing prototype solutions are solving the problem of mass customizations for startups and small businesses. With traditional methods, executing mass personalization is complex, expensive and time-consuming. However, with the additive process, 3d printing machines can accelerate the customization process by maintaining a high repeatability rate. It is a cutting-edge benefit to small companies that need to manufacture personalized products in bulk. Companies working in the automotive, dental, or consumer industry that demand customization can get massive benefits from 3d printing.

Organized Storage Management

Growing manufacturing companies often face storage challenges while scaling up their businesses. Producing products in bulk then safely storing and shipping them is a complex task to perform daily. 3d printing technology dilutes this challenge by allowing companies to create inventory depending on the demand. It helps companies to reduce their high manufacturing and storage costs. As all designs and 3d models are available in digital format, organizing storage becomes much cheaper.

Significant Quality Improvement

When comparing 3d printing with conventional manufacturing, the scope for quality improvement is much higher in the additive process. As companies can change materials, try different 3d printing methods, pick from multiple surface finishing — product quality improves. The traditional techniques offer scope for improvements, but it’s finite, and the execution is expensive. This different approach towards product improvement gives the company an edge over others. With rapid prototyping, experimenting with design and aesthetics becomes more convenient.

Lower Material Wastage

Material wastage is a critical problem for both small and big companies. The traditional manufacturing process works on a subtractive model in which the material block is carved. In this approach, the material wastage is on the higher side. However, 3d printing technology solves this problem as it an additive process. The printing machine only uses the needful amount of material to follow the CAD file’s instruction. Due to this, engineers can use the remaining material for other projects anytime in the future.

Limited Equipment

If a small company plans to set up an in-house 3d printing unit, the investment is limited depending upon the manufacturing requirement. Business owners only need to buy the printing machines and the training of their in-house team. Contrary to expanding a traditional production setup, companies need to invest heavily in equipment and additional support infrastructure. Considering this advantage, small business owners gain a competitive edge to invest more capital in innovation and product than in equipment.

Less Workforce

As the equipment for producing objects is lower, companies need less workforce to handle the manufacturing process. And, if the company decides to outsource their requirements, it becomes more cost-effective to scale business. In current times, where companies are working with limited resources and human resources, 3d printing is an ideal addition to businesses regardless of industries. Additionally, the 3d printing method is very adaptive, and it is also possible to operate the process remotely.

Why opt for A Professional 3d Printing Service Provider?

With ever-changing customer demands and market trends, it has become mandatory for small businesses to stay relevant in their respective industries. By opting for professional 3d printing services, companies can innovate, produce, and grow their distribution network cost-effectively.

When companies partner with 3d printing service providers, they access their expertise, modern machines, and premium materials. Small and medium-sized agencies can improve their product quality and grow their customer base by offering personalized solutions.

Many companies are now offering full 3d printing in Australia, New Zealand and several other places to help startups and growing businesses. If you plan to transform your business with 3d printing, it is the right time to go ahead.