Modern-day engineering is transforming how things are designed, prototyped, and made across industries. Be it the automotive industry, aerospace, construction, or medical — companies are leveraging seamless solutions to accomplish complex tasks faster. Among several applications, reverse engineering is a transforming advancement that is revolutionizing the entire industrial domain.

The automotive and industrial sectors bring in several product designing challenges, and reserve engineering helps engineers streamline their work with its accurate applications. Be it analyzing existing design, reconstructing a product, or improvising the existing structural durability — the advantages are endless.

Using robust 3d reverse engineering applications, companies can comprehensively examine the design vulnerabilities and improve the overall performance. Compared to traditional processes, this advancement is fast, accurate, and more reliable. Before we dive into the robust benefits, let’s have a look at what is reverse engineering.

Reverse Engineering brief overview

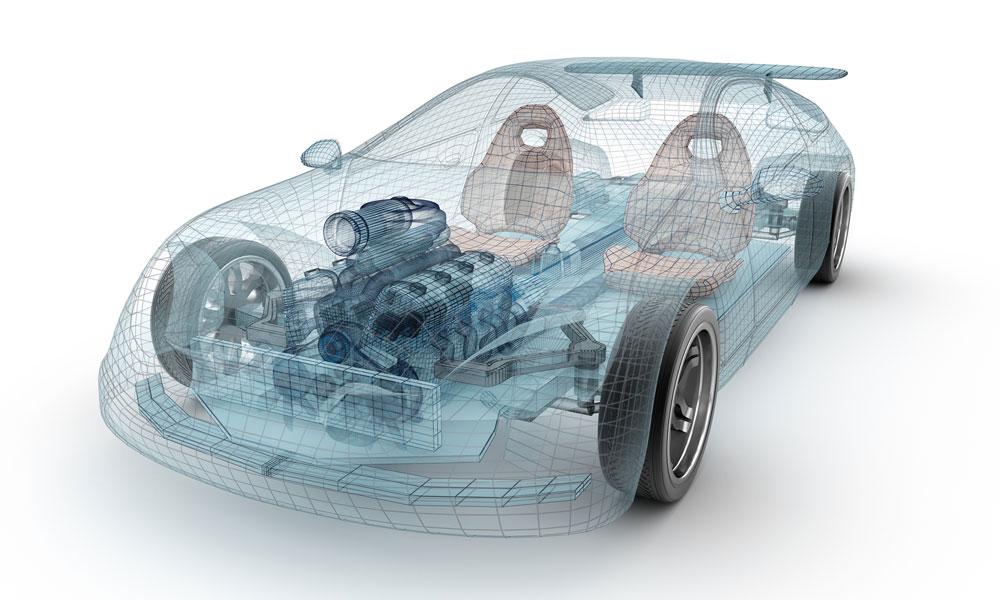

Reverse engineering is a process in which technicians deconstruct the object to explore its design information and gather vital information. The primary purpose of reverse engineering is to examine the existing design state and improvise it to drive more efficiency and performance. Using this process, engineers can explore how a particular spare part was designed and made to recreate it.

The automotive and industrial sector often use this process to deep dive into an object’s intricate geometrical structure to understand the design flow layer-by-layer. The reverse engineering process improves the information gathering scope while working on design efficiency. It is a popular method to extract useful information from spare parts or objects no longer available in the market.

Reverse engineering bridges the efficiency gap by allowing technicians to gather design flaws and fix them for cutting-edge performance. This process amplifies the scope of creating highly durable products that offer a higher lifecycle in the real-world environment. On this note, let’s explore how this technology is bringing a paradigm shift in the industrial and automobile sectors.

Explore existing design

Reverse engineering eases product analysis with its accurate data coordination system, and lets technicians collect valuable information quickly. Engineers can explore the existing product and figure out the structural shortcomings without performing any manual task. To stay relevant in the business, companies have to keep optimizing their product line up, and reverse engineering helps engineers achieve the same.

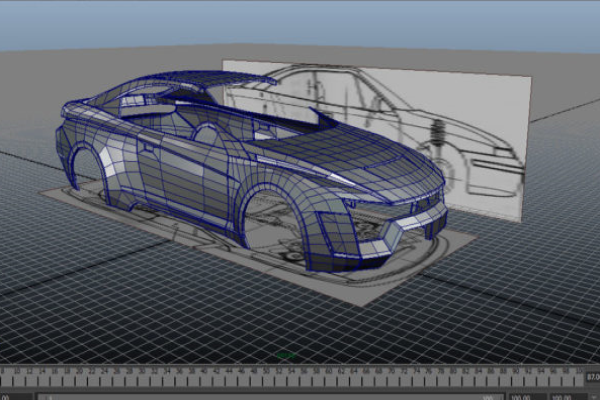

Using a 3d scanner, engineers scan the object in a 360° manner to collect all data points with higher accuracy. Once the scanning is complete, engineers draft a highly detailed CAD model to comprehensively visualize the design structure.

In the automotive domain, where OEM companies need to offer on-demand services to their customers, reverse engineering plays a winning role. Using this technology, engineers can quickly scan the damaged part and create its 3d model. Once the 3d CAD model is ready, they can start manufacturing the product and deliver it in a shorter turnaround time. This process saves a lot of time in manually examining the object.

Reconstructing outdated products

Thousands of automotive engineering products are available in the market, and many of them become outdated as companies stop manufacturing time. As these parts are still being used in vehicles, finding the exact spare part when the original one is damaged is challenging. In such scenarios, reverse engineering comes into execution and helps automotive companies to build a similar product.

For making the product remanufacturing process easier, engineers need to 3D scan the spare part to gather all structural data. Once the data is available in the form of a 3D CAD model, it’s easier to print it using additive manufacturing technology.

With this approach, companies save a lot of time and money by eliminating excessive manual work and design iteration. As the older design is available in digital format, it is hassle-free to improvise the part to eliminate the structural flaws and build a much better and more efficient part. Reverse engineering is a boon for automotive and industrial OEM that reconstruct obsolete parts.

Identifying product vulnerabilities

As we move towards Industry 4.0 transformation, customers demand efficient parts that can offer more value. Reverse engineering is the only way to make products long-lasting and efficient in real-life conditions. It’s much easier to find faults in the product’s existing design at a very early development stage. With the conventional process, it’s difficult to quickly find out vulnerabilities, leading to product recall after the distribution phase.

3d scanning reverse engineering can streamline a design into a new configuration and make the older design meet the contemporary industrial standards. This process helps engineers define an improvisation path for a product at a minimized cost. CAD models can mimic the product’s mechanics’ exact functionality and help engineers study the working internals with ease.

Both automotive and industrial sectors need to deal with a frequent maintenance cycle, and with reverse engineering, it is possible to optimize it. By analyzing the fixing the product vulnerabilities, companies can improve the maintenance cycle and let the products serve for a longer time. The most significant benefit of reverse engineering is that companies don’t need to build the product from scratch once they discover vulnerabilities.

Affordable products

The primary goal of this process is to drive innovation, efficiency, and cost-effectiveness across industries. Engineers can develop a cost-effective manufacturing process that will let them offer quality products at a much lower price. Reverse engineering optimizes the product designing cycle, and it helps in reducing the overall manufacturing time.

Be it product analysis, CAD drafting, designing, and manufacturing; reverse engineering saves substantial efforts and resources. With comprehensive automotive reverse engineering, designers can analyze and cut down the unnecessary geometrical composition in a product. It helps companies save material and allows them to align the design with modern industrial standards.

Earlier, the recreation of damaged parts was an expensive, painstaking, and resource-intensive task. However, with reverse engineering’s accurate measurement, the process is easy to complete in a couple of hours or days. This distinctive property is creating a transforming difference and allowing companies to scale their business faster.

Companies can also take a competitive advantage by reverse engineering and offering better products at lower costs. This technology speeds up the R&D process and lets companies recreate items at a lower price, and maximize the market distribution.

Higher reusability

Reusability plays a significant time and money-saving role in industrial product design. Using reverse engineering, companies can prepare CAD models to keep for future design reuse and save time. As the 3d CAD models have all the comprehensive geometrical data of the product, engineers can tweak it to create an improved version without doing it from scratch.

In the case of legacy projects where older technologies might become obsolete, reverse engineering helps companies preserve essential findings and information. The 3d CAD models act as design documentation for future reusability when engineers opt for modern technology to recreate the legacy product.

In the automotive industry, where customers seek a modified version of older parts, reverse engineering comes handy in preserving the data and structural information. The majority of engineering procedures cover creating a CAD file that engineers can use for design analysis if future issues arrive. This advancement improves the manufacturing team’s productivity and product efficiency.

Ability to innovate

Innovation is the core of automotive and industrial manufacturing domains that keep things moving. With ongoing modern trends and changing market demands, companies need to keep innovating and improving their existing lineup. For making this process seamless, reverse engineering lets designers and technicians innovate new designs with higher accuracy.

In the conventional process, upgrading a product’s design and aesthetics is a time-consuming task. It would take weeks or even months to get the new design right and fix vulnerabilities. Due to excessive manual efforts, the overall product delivery cycle becomes longer and slower.

However, engineers now have a much broader scope of innovating design and testing the feasibility in real-time using various testing procedures. CAD modelling brings in superior automation, and it helps designers avoid design errors in real-time while conceptualizing the structure. So even when companies launch innovative products, the chances of functionality failure in real-world usage are much lower. As companies can complete their iterative testing in less time, the time to market gets shorter.

Future of reverse engineering in multiple industries

With growing demands for high-quality products at lower prices, there is a high demand for reverse engineering in traditional manufacturing and 3d printing. The market capital of additive manufacturing will be USD 54.96 billion by 2027, and reverse engineering is playing a significant role in fueling this domain.

Automotive and industrial domains are pushing their limits to innovate and present better products to their customers. Only this advancement can help them take an edge in the competitive market by speeding up the process.

Be it spare parts manufacturing, vehicles customization, or better product innovation, the scope of this technology is never-ending in 2021 and beyond. If you are not leveraging the potential of this technology, it’s the right time to adopt it and open opportunity doors to innovate, produce, and treat your customers with higher performance-driven products or services.

![TamilMV Proxy List Top 30+ [Unblock TamilMV Sites] TamilMV Proxy Unblock](https://technewsgather.com/wp-content/uploads/2023/04/17825836_SL-121019-25870-14-1-100x70.jpg)