3D printing has come leaps and bounds since it was created back in the 1980s. The technology has evolved significantly, allowing manufacturers to leverage it in new ways. Companies across industries as diverse as military and defense to medical sciences and academia have found a use for additive manufacturing.

3D printing’s capacity to transform many of our manufacturing and business processes is vast. In fact, it’s no longer a strictly business-specific technology; It has a number of consumer applications that are only going to grow in the years ahead.

Here are seven reasons why 3D printing is going to be so integral to our society in the coming years.

1. Speed

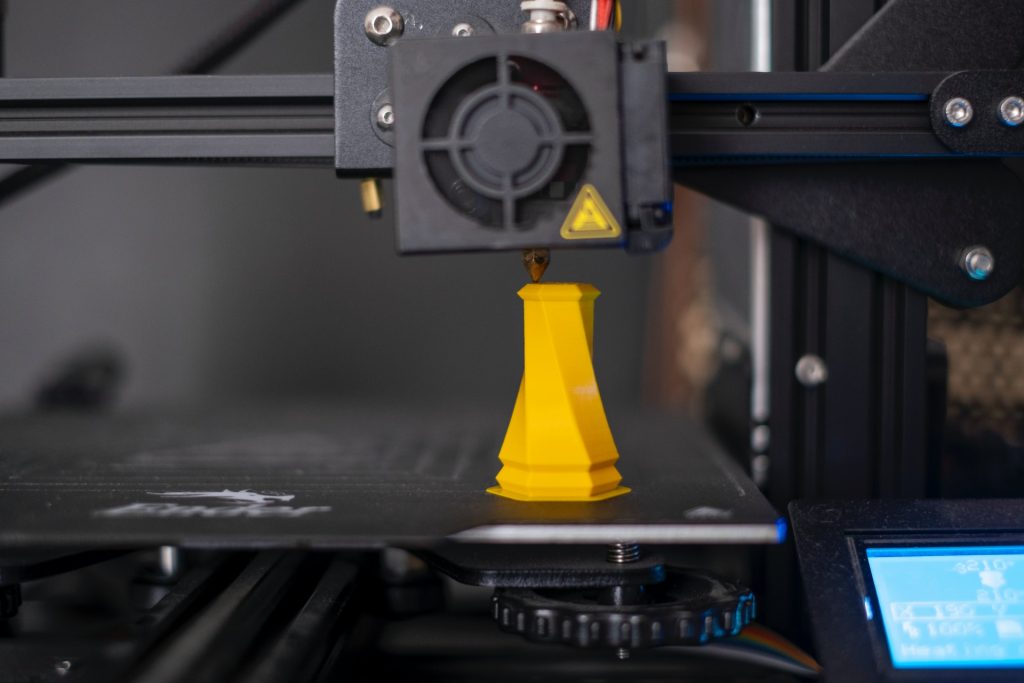

Speed is one of the biggest advantages of 3D printing, especially for small-batch production. With conventional manufacturing techniques like injection molding, it can take days or weeks to build out a suitable mold before you can churn out the products.

With 3D printing, you can speed up the process substantially and execute a similar run of products in as little as a few days. This makes it an ideal fit for prototyping and trial runs. On a desktop 3D printer, you can usually have a part printed overnight, and large professional services can do the same in as little as two to five days.

This significantly accelerates new product design and development for companies. Products that would typically require nine months to perfect can now be finished in a matter of weeks.

2. Customizable Designs

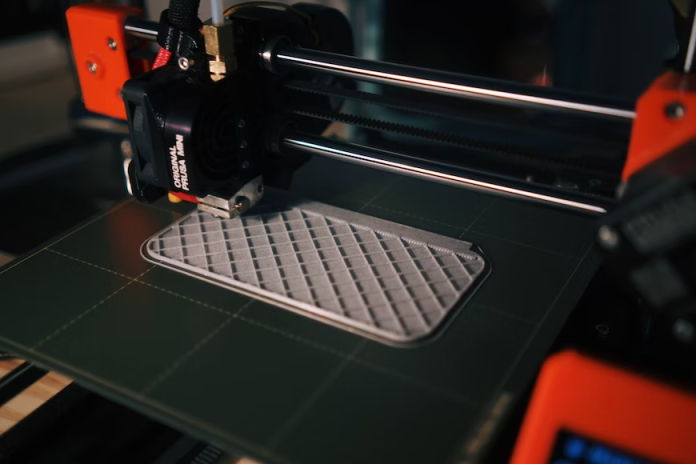

3D printing allows you to incorporate a great deal of geometric complexity into your designs at no extra cost. The nature of additive manufacturing means that complex shapes are easy to render. Manufactured conventionally, a number of these parts may require a combination of complex molds and hand finishing, which drives up both costs and turnaround time.

With a 3D printer, you can easily produce products with geometrically advanced shapes at the same cost and scale of simpler parts finished via conventional means. You can also use a greater variety of materials, including ceramics, glass, and metal powders to name a few, in the creation of unique designs.

3. Low Startup Costs

With traditional manufacturing techniques, such as injection molding and metal casting, the manufacture of any part requires a unique mold. Hot metal or plastic is then injected into this mold and cooled to give you the finished product. As you can imagine, something like prototyping is incredibly expensive with this sort of an approach, where for every subsequent iteration, you have to create a new mold until you’ve perfected it.

Businesses typically recoup their costs by leveraging economies of scale when they manufacture thousands of the same kind of product. This means that if you only receive small orders for each type, you can’t break even.

With 3D printing, you have a one-time investment of printing and scanning technologies that you can use to iterate as many times as you like and produce as many finished articles as you need, without worrying about driving up costs. What’s more, given the advances in technology in recent years, 3D printers are available at a much more accessible price point, making it a very viable option for most businesses.

4. Flexible Supply Chains

Additive manufacturing gives you the advantage of on-demand printing. Since you’re not constrained by high innovation and prototyping costs, you can essentially produce a batch of articles to order. If buyers only need a few hundred parts to tide them over for a period, you have the advantage over other conventional suppliers who would demand order quantities in the thousands to make it feasible.

This is a significant advantage to have with countries worldwide still dealing with supply chain crises. 3D printing lets you cater to specific demand in bespoke fashion, saving costs, time, and materials.

5. Versatile

3D printing is a very versatile technology that can be applied in a range of industries. In its early days, it was traditionally applied to industrial manufacturing. However, it has a wide variety of uses for practically any sector you can think of.

One of its most unexpected successes has been its application in the medical and healthcare space. With this technology, scientists can create incredibly lifelike models of bones and human organs, both for academic and practical purposes, including orthopedic surgery, prosthetic limbs, and organ transplants.

3D printing’s use in fields such as electronics and defense manufacturing has surged, owing to its ability to provide critical parts on call at short notice.

6. Sustainable Manufacturing

Sustainability and conservation are principles integral to additive manufacturing. This technology reduces, if not eliminates, waste material, since products are manufactured so precisely.

With traditional manufacturing, you often have significant wastage, where parts are carved out from large chunks of non-recyclable materials. 3D printing offers you a much more eco-friendly option by using only as much is needed. It’s also a more fuel-efficient process and recent advances have made it possible for manufacturers to explore materials like bio-based plastics, making it even more attractive.

3D printing adoption is expected to grow by leaps and bounds in the years ahead. Consumer technologists even expect people to have their own personal-use 3D printers to quickly create limited quantities of organic and inorganic products. Given the host of applications for this technology and its rapidly decreasing cost, 3D printing may well prove to be the cornerstone of a revolution in how society operates in the future.

![TamilMV Proxy List Top 30+ [Unblock TamilMV Sites] TamilMV Proxy Unblock](https://technewsgather.com/wp-content/uploads/2023/04/17825836_SL-121019-25870-14-1-100x70.jpg)